47mm Friction Bolt is mainly used as primary support in mechanized jumbo development and production mining.

It is one of the standard Friction Bolt widely used in worldwide projects of mining, tunnels, and dams as rock support material.

Different thicknesses are available, such as 3.0mm, 3.2mm

Both galvanizing and black are available.

The 47mm friction bolt stabilizer is a type of ground support tool commonly used in mining, tunneling, and other geotechnical applications to stabilize rock and soil.

Diameter: 47mm (approximately 1.85 inches)

Material: High-strength steel, often with a galvanized or coated finish to resist corrosion.

Length: Available in various lengths, typically ranging from 1.2 meters (4 feet) to 3.6 meters (12 feet), depending on the application.

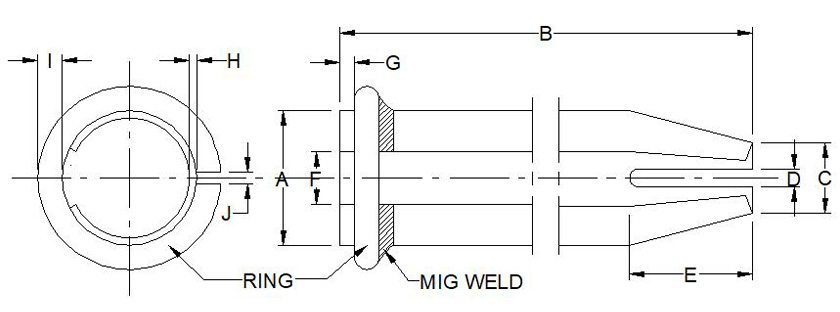

Design: A tube-like structure with a slot along its length that allows it to compress when driven into a hole, creating friction against the rock surface.

Installation: Easily installed using a jumbo or handheld drill rig, often with a driving cap to protect the bolt during installation.

Accessories: Often used in conjunction with bearing plates and domed plates to distribute the load and provide additional support.

| DIMENSIONS | ||

| Bolt Diameter | A | 47mm |

| Bolt Length | B | 600-3000mm |

| Taper End Diameter | C | 38mm |

| Taper Slot Wide | D | 2mm |

| Taper Length | E | 65mm |

| Bolt Slot Wide | F | 25mm |

| Ring Location | G | 8mm |

| Material Guage | H | 2.5-3.2mm |

| Ring Wire Guage | I | 8mm |

| Ring Open Gap | J | 6.0-7.0mm |

| PHYSICAL PROPERTIES | TECHNICAL DATA | ||

| Yield Strength | Min. 345 Mpa (120KN) Typical 445 Mpa (150KN) | Recommended Norminal Bit Size | 41-45mm |

| Tube Ultimate Tensile Strength | Min. 470 Mpa (160KN) Typical 530 Mpa (180KN) | Typical Breaking Capacity | 178KN |

| Mass per Meter | 2.71 Kgs | Minimum Breaking Capacity | 133KN |

| Cross Section Area | 345 mm² | Recommended Initial Anchorage | 6 - 10 Tons (53 - 89 KN) |

| Hole Diameter Range | 43-45.5mm | Ultimate Axial Strain | Typical 21% (Thickness<16mm) |

| TRM Bolt Code | Bolt Description | Diameter (mm) | Length (mm) | Surface Finish | Weight (Kgs) | Pack QTY (Pcs) | Ring Color ID |

| FB47-0900 | Friction Bolt 47x0900 | 47 | 900 | Untreated | 2.50 | 150 | |

| FB47-1800 | Friction Bolt 47x1800 | 47 | 1800 | Untreated | 5.10 | 150 | |

| FB47-2100 | Friction Bolt 47x2100 | 47 | 2100 | Untreated | 6.10 | 150 | |

| FB47-2400 | Friction Bolt 47x2400 | 47 | 2400 | Untreated | 6.70 | 150 | |

| FB47-3000 | Friction Bolt 47x3000 | 47 | 3000 | Untreated | 8.60 | 150 | |

| FB47-0900G | Friction Bolt 47x0900 HDG | 47 | 900 | Hot Dip Galv. | 2.60 | 150 | |

| FB47-1800G | Friction Bolt 47x1800 HDG | 47 | 1800 | Hot Dip Galv. | 5.50 | 150 | Red |

| FB47-2100G | Friction Bolt 47x2100 HDG | 47 | 2100 | Hot Dip Galv. | 6.40 | 150 | Green |

| FB47-2400G | Friction Bolt 47x2400 HDG | 47 | 2400 | Hot Dip Galv. | 7.05 | 150 | |

| FB47-3000G | Friction Bolt 47x3000 HDG | 47 | 3000 | Hot Dip Galv. | 9.00 | 150 | Yellow |

As a leading manufacturer of Friction Bolt products in China, we are an ISO9001-certified company, with more than ten years of experience in producing and distributing super qualified friction bolts as well as all kinds of bearing plates and other related products used in the project of ground support, we have been supplying our products to many customers from all over the world including quite a few famous mining companies like Rio Tinto and BHP etc.

We are a friction bolt manufacturer and supplier, providing a variety of support products and a full range of accessories to solve the problems of ground support projects. If you don't find the ground support products you need here, please contact us.

Here are some photos of our 47mm friction bolt stabilizers products:

Supper Qualified Welding

|  |  |

Advanced Professional Facilities

|  |  |

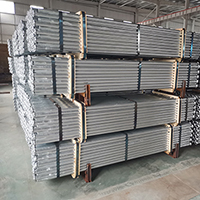

Huge Capacity and Stock

|  |  |

▶ Drill Hole: A hole is drilled into the rock or soil to the required diameter and depth.

▶ Insert Bolt: The friction bolt is inserted into the hole and driven in using a hammer or drill rig.

▶ Secure Plate: A bearing plate is placed over the bolt and secured to provide additional surface support.

▶ Tensioning: The friction bolt creates tension as it compresses against the hole walls, providing stability.

How Does a Friction Bolt Work?

Dec. 13, 2024The Role of Anchor Bolts in Tunnel Support

Nov. 19, 2024