-

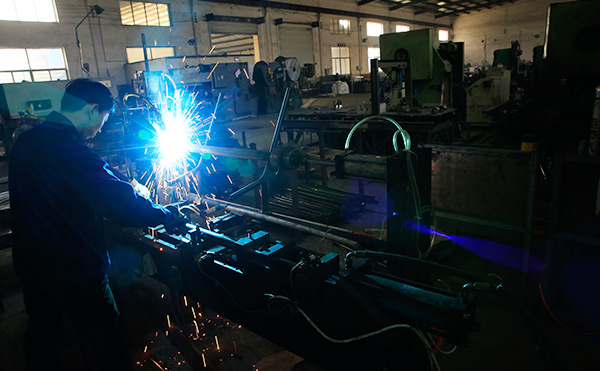

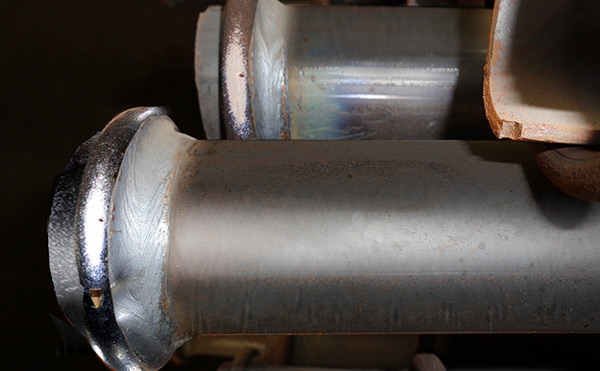

ADVANTAGE FACILITIESWith our own technologies and experiences, working together with professional manufacturer of rollforming and welding facilities, we designed and made an advantage rollforming line and auto-welding facilities for our production of Friction Bolt. Following the international latest technology, we are keeping to improve our facilities to make it more efficiency, more stable, and more qualified. Our rollforming line is an completely automatic line, which with automatic feeding, pressing, forming and cutting, and our non-stop following cutting technology makes the rollforming more efficiency. Our welding facility is also an automatic one, it can finish end taper, on-ring and welding one time, with self-checking device process, making an consistent welding quality.

ADVANTAGE FACILITIESWith our own technologies and experiences, working together with professional manufacturer of rollforming and welding facilities, we designed and made an advantage rollforming line and auto-welding facilities for our production of Friction Bolt. Following the international latest technology, we are keeping to improve our facilities to make it more efficiency, more stable, and more qualified. Our rollforming line is an completely automatic line, which with automatic feeding, pressing, forming and cutting, and our non-stop following cutting technology makes the rollforming more efficiency. Our welding facility is also an automatic one, it can finish end taper, on-ring and welding one time, with self-checking device process, making an consistent welding quality. -

PROFESSIONAL & EXPERIENCEWith more than 10 years of experiences in the line of underground support industry, we have been becoming a professional manufacturer and supplier of Friction bolt and Plate and its accessories, and become one of the leading supplier in China. Almost all of our bolts and plates are exported to international market such as Australia, South Africa, Russia, and some Asia areas etc. Working with some of the international leading companies in the line of Mining underground industry, we got rich experiences in how to make and control a qualified product, and follow the leading international technology of the industry, combining with our own technologies to build a full set of system in production, quality control, tracking and inspection area. Our final Top Rank Mission is SAFETY

PROFESSIONAL & EXPERIENCEWith more than 10 years of experiences in the line of underground support industry, we have been becoming a professional manufacturer and supplier of Friction bolt and Plate and its accessories, and become one of the leading supplier in China. Almost all of our bolts and plates are exported to international market such as Australia, South Africa, Russia, and some Asia areas etc. Working with some of the international leading companies in the line of Mining underground industry, we got rich experiences in how to make and control a qualified product, and follow the leading international technology of the industry, combining with our own technologies to build a full set of system in production, quality control, tracking and inspection area. Our final Top Rank Mission is SAFETY -

QUALITY CONTROLWe have a double-track quality control system, which has been proved to be an excellent system and had a very good performance in our daily production. One track is focused on each process, which we called it as on-site self-checking by our production staff, it could keep each processes away from the quality issues from the beginning. The second track is focused on each stage of production and be responsibility by our professional inspector. Sampling inspection in each different stage of production will tell the quality level, and feedback to production staff. The two tracks will help and complement each other, and be sure a qualified product supplied by us. View Details of our Quality Control system, Click here. Our final Top Rank Mission is SAFETY

QUALITY CONTROLWe have a double-track quality control system, which has been proved to be an excellent system and had a very good performance in our daily production. One track is focused on each process, which we called it as on-site self-checking by our production staff, it could keep each processes away from the quality issues from the beginning. The second track is focused on each stage of production and be responsibility by our professional inspector. Sampling inspection in each different stage of production will tell the quality level, and feedback to production staff. The two tracks will help and complement each other, and be sure a qualified product supplied by us. View Details of our Quality Control system, Click here. Our final Top Rank Mission is SAFETY